Quality Inspection for China Reducer Type Rubber Expansion Joint Flanged DIN / BS / JIS / ANSI / ASA

Our intention would be to provide top quality products and solutions at competitive charges, and top-notch support to customers around the world. We have been ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Quality Inspection for China Reducer Type Rubber Expansion Joint Flanged DIN / BS / JIS / ANSI / ASA, We hope we are able to have a pleasant partnership with businessman from all over the environment.

Our intention would be to provide top quality products and solutions at competitive charges, and top-notch support to customers around the world. We have been ISO9001, CE, and GS certified and strictly adhere to their quality specifications for China Rubber Expansion Joint, Reducer Expansion Joint, Should really any of those items be of curiosity for you, you should allow us to know. We’ll be satisfied to give you a quotation on receipt of one’s thorough specs. We now have our personal experienced R&D enginners to meet any of one’s requriements, We appear forward to receiving your enquires soon’and hope to have the opportunity to work together with you in the future. Welcome to check out our company.

Details

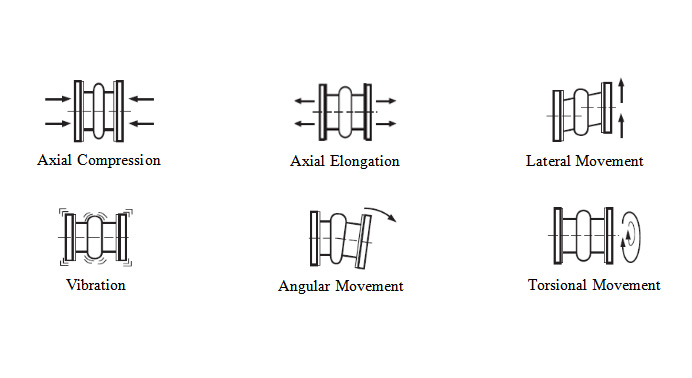

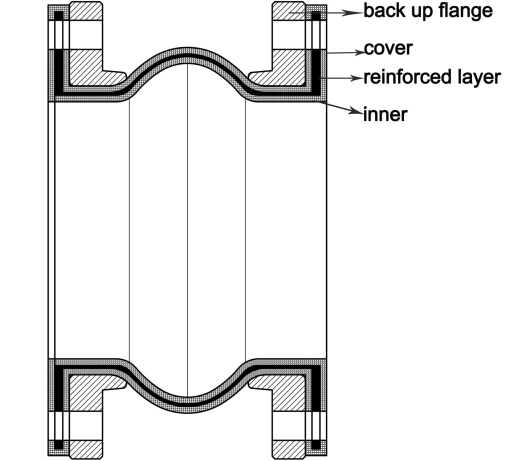

Wide arch system is the molded expansion joint, with integral flange and without a metal reinforcement at the neck of the body. Wide arch allows greater movements and low spring rates comparing to spool type. WA and WAF is used for an economical wide arch rubber expansion joint. WAF is filled arch, with 50% of the WA allowed movements, but it has 4 times spring rates than wide arch.

| Specifications | I | II | III |

| Working Pressure Mpa (Kgf/Cm2) | 1Mpa (10) | 1.6 (16) | 2.5 (25) |

| Test Pressure | 1.5Mpa | 2.4Mpa | 3.75Mpa |

| Burst Pressure Mpa (Kgf/Cm2) | 3 (30) | 4.8 (48) | 5.5 (55) |

| Vacuum Kpa (Kgf/Cm2) | 53 (400) | 86(660) | 100 (750) |

| Materials | EPDM/NBR/SBR/NR | ||

| Diameter Range | DN15-DN600 (1/2″-24″) | ||

| Connection Method | FLANGETHREADCLAMP | ||

| Flanges Dimensions | DIN, EN,ANSI, BS, JIS and other standards | ||

| Applicable Medium | Air, compressed air, water, seawater, hot water, oil, acid, alkali etc. | ||

| Loading Port: | Qingdao, China | ||

| Shipment Terms: | FOB, CFR, CIF | ||

| Production Capacity: | 50000 set | ||

| Payment Terms: | L/C, T/T, D/P | ||

| Connection: | Flange, Thread | ||

| Flange Material: | Carbon Steel, Stainless Steel | ||

| Period of Delivery | about 21 working days | ||

|

WIDE ARCH (WA)-American Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. (psi)-3,-4 |

Max Vacuum (in. of Hg)-5 |

|

|

Inch |

mm |

Inch |

Inch |

Inch |

Inch |

|||

|

2″ |

50 |

6″ |

1-3/4″ |

3/4″ |

±3/4″ |

35° |

150 |

15 |

|

2 1/2″ |

65 |

6″ |

1-3/4″ |

3/4″ |

±3/4″ |

30° |

150 |

15 |

|

3″ |

80 |

6″ |

1-3/4″ |

3/4″ |

±3/4″ |

30° |

150 |

15 |

|

4″ |

100 |

6″ |

1-3/4″ |

3/4″ |

±3/4″ |

25° |

150 |

15 |

|

5″ |

125 |

6″ |

1-3/4″ |

3/4″ |

±3/4″ |

25° |

150 |

15 |

|

6″ |

150 |

6″ |

1-3/4″ |

3/4″ |

±1″ |

20° |

150 |

15 |

|

8″ |

200 |

6″ |

1-3/4″ |

3/4″ |

±1″ |

20° |

150 |

15 |

|

10″ |

250 |

8″ |

1-3/4″ |

3/4″ |

±1″ |

15° |

150 |

15 |

|

12″ |

300 |

8″ |

1-3/4″ |

3/4″ |

±1″ |

15° |

150 |

15 |

|

14″ |

350 |

8″ |

2″ |

7/8″ |

±1-1/8″ |

12° |

150 |

10 |

|

16″ |

400 |

8″ |

2″ |

7/8″ |

±1-1/8″ |

12° |

150 |

10 |

|

18″ |

450 |

8″ |

2″ |

7/8″ |

±1-1/8″ |

9° |

150 |

10 |

|

20″ |

500 |

8″ |

2″ |

7/8″ |

±1-1/8″ |

9° |

150 |

10 |

|

24″ |

600 |

10″ |

2-1/4″ |

1″ |

±1-1/8″ |

9° |

150 |

10 |

|

WIDE ARCH: FILLED ARCH (WAF)-American Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. (psi)-3,-4 |

Max Vacuum (in. of Hg)-5 |

|

|

Inch |

mm |

Inch |

Inch |

Inch |

Inch |

|||

|

2″ |

50 |

6″ |

7/8″ |

3/8″ |

±0.875″ |

17.5° |

150 |

15 |

|

2 1/2″ |

65 |

6″ |

7/8″ |

3/8″ |

±0.875″ |

15° |

150 |

15 |

|

3″ |

80 |

6″ |

7/8″ |

3/8″ |

±0.875″ |

15° |

150 |

15 |

|

4″ |

100 |

6″ |

7/8″ |

3/8″ |

±0.875″ |

12.5° |

150 |

15 |

|

5″ |

125 |

6″ |

7/8″ |

3/8″ |

±0.875″ |

12.5° |

150 |

15 |

|

6″ |

150 |

6″ |

7/8″ |

3/8″ |

±0.50″ |

10° |

150 |

15 |

|

8″ |

200 |

6″ |

7/8″ |

3/8″ |

±0.50″ |

10° |

150 |

15 |

|

10″ |

250 |

8″ |

7/8″ |

3/8″ |

±0.50″ |

7.5° |

150 |

15 |

|

12″ |

300 |

8″ |

7/8″ |

3/8″ |

±0.50″ |

7.5° |

150 |

15 |

|

14″ |

350 |

8″ |

1″ |

7/16″ |

±0.563″ |

6° |

150 |

10 |

|

16″ |

400 |

8″ |

1″ |

7/16″ |

±0.563″ |

6° |

150 |

10 |

|

18″ |

450 |

8″ |

1″ |

7/16″ |

±0.563″ |

4.5° |

150 |

10 |

|

20″ |

500 |

8″ |

1″ |

7/16″ |

±0.563″ |

4.5° |

150 |

10 |

|

24″ |

600 |

10″ |

1.125″ |

1/2″ |

±0.563″ |

4.5° |

150 |

10 |

|

Wide Arch-Standard Length |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Standard O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) Kmpa |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

1 1/2″ |

40 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2″ |

50 |

105 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2 1/2″ |

65 |

115 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

3″ |

80 |

130 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

4″ |

100 |

135 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

5″ |

125 |

170 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

6″ |

150 |

180 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

8″ |

200 |

205 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

10″ |

250 |

240 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

12″ |

300 |

260 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

14″ |

350 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

16″ |

400 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

18″ |

450 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

20″ |

500 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

24″ |

600 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

Jessy Lin

-

WeChat

Ellen Zhang